The Environmental Impact of hydroponics farming

Author: Arjina Shrestha, Bruce Dunn

Hydroponics - Oklahoma State University. 1 Apr. 2017,

0 General Document comments

0 Sentence and Paragraph comments

0 Image and Video comments

Introduction

“HYDROPONICS” is the growing of plants in a liquid nutrient solution with or without the use of artificial media.

Commonly used mediums include expanded clay, coir, perlite, vermiculite, brick shards, polystyrene packing peanuts and wood fiber.

Hydroponics has been recognized as a viable method of producing vegetables (tomatoes, lettuce, cucumbers and peppers) as well as ornamental crops such as herbs, roses, freesia and foliage plants.

Due to the ban on methyl bromide in soil culture, the demand for hydroponically grown produce has rapidly increased in the last few years.

History

The word hydroponics comes from two Greek words ‘hydro’ meaning water and ‘ponos’ meaning labor. This word was first used in 1929 by Dr. Gericke, a California professor who began to develop what previously had been a laboratory technique into a commercial means of growing plants. The U.S. Army used hydroponic culture to grow fresh food for troops stationed on infertile Pacific islands during World War II. By the 1950s, there were viable commercial farms in America, Europe, Africa and Asia.

Advantages

- It can be used in places where in-ground agriculture or gardening is not possible (for example, dry desert areas or cold climate regions).

- More complete control of nutrient content, pH and growing environment.

- Lower water and nutrient costs associated with water and nutrient recycling.

- Faster growth due to more available oxygen in root area.

- Elimination or reduction of soil related insects, fungi and bacteria.

- Much higher crop yields.

- No weeding or cultivation required.

- Some crops, such as lettuce and strawberries, can be lifted from ground level to a much better height for planting, cultivation and harvesting. This gives much better working conditions and hence lowers labor costs.

- Crop rotation/fallowing is not necessary.

- Transplant shock is reduced.

Disadvantages

- Initial and operational costs are higher than soil culture.

- Skill and knowledge are needed to operate properly.

- Some diseases like Fusarium and Verticillium can spread quickly through the system. However, many varieties resistant to the above diseases have been bred.

Growing Systems

Hydroponic systems can either be liquid or aggregate. Liquid systems have no supporting medium for the plant roots; whereas, aggregate systems have a solid medium of support. Hydroponic systems are further categorized as open (once the nutrient solution is delivered to the plant roots, it is not reused) or closed (surplus solution is recovered, replenished, and recycled).

Liquid Hydroponic System:

They are closed systems.

- Nutrient Film Technique (NFT): Plants are placed in a polyethylene tube that has slits cut in the plastic for the roots to be inserted. Nutrient solution is pumped through this tube.

- Floating Hydroponics: Plants are grown on a floating raft of expanded plastic.

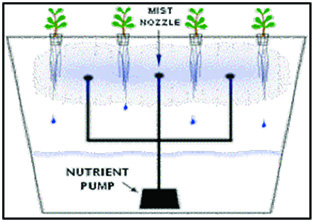

- Aeroponics: Plant roots remain suspended in an enclosed growing chamber, where they are sprayed with a mist of nutrient solution at short intervals, usually every few minutes.

Aggregate Hydroponic System:

Open system:

- Rockwool Culture: It is the most widely used medium in hydroponics. Rockwool is ground-up basalt rock that is heated then spun into threads making wool. It is very light and is often sold in cubes. Rockwool can hold water and retain sufficient air space (at least 18 percent) to promote optimum root growth.

- Sand Culture

Closed System:

- Gravel

- NFT and Rockwool: Plants are established on small rockwool slabs positioned in channels containing recycled nutrient solution.

These system are further categorized into:

- passive systems

- active systems

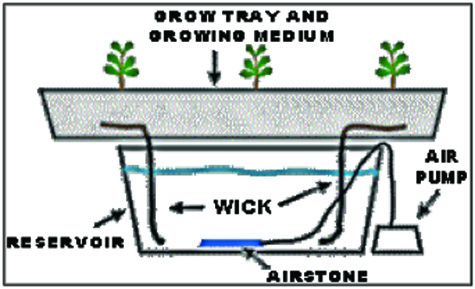

1. Passive systems use a wick and growing media with very high capillary action. This allows water to be drawn to the plant roots. The Wick System is by far the simplest type of hydroponic system (Figure 1.)

Figure 1. The Wick System.

2. Active systems work by actively passing a nutrient solution over your plants roots. Examples include:

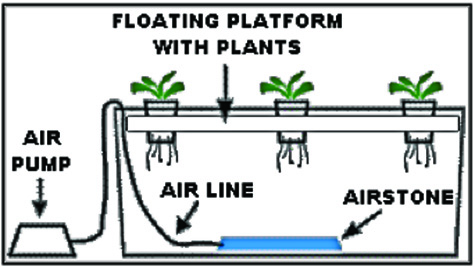

The Water Culture System is the simplest of all active hydroponic systems. The platform that holds the plants is usually made of Styrofoam and floats directly on the nutrient solution. An air pump supplies air to the air stone that bubbles the nutrient solution and supplies oxygen to the roots of the plants (Figure 2).

Figure 2. The Water Culture System.

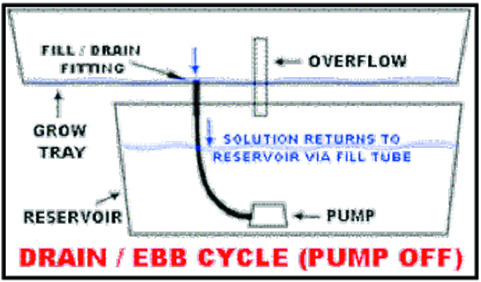

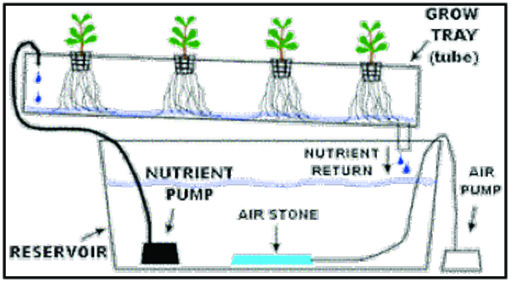

The Ebb and Flow System works by temporarily flooding the grow tray with nutrient solution and then draining the solution back into the reservoir. This action is normally done with a submerged pump that is connected to a timer. The timer is set to come on several times a day, depending on the size and type of plants, temperature, humidity and the type of growing medium used (Figure 3).

Figure 3. The Ebb and Flow System.

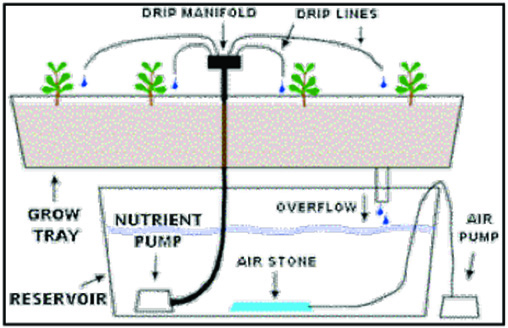

Drip Systems are probably the most widely used type of hydroponic system in the world. A timer controls a submersed pump. The timer turns the pump on and nutrient solution is dripped onto the base of each plant by a small drip line (Figure 4).

Figure 4. The Drip System.

NFT Systems have a constant flow of nutrient solution, so no timer is required for the submersible pump (Figure 5).

Figure 5. The NFT System.

The Aeroponic System is probably the most high-tech type of hydroponic gardening. A timer controls the nutrient pump much like other types of hydroponic systems, except the aeroponic system needs a short cycle timer that runs the pump for a few seconds every couple of minutes (Figure 6).

Figure 6. The Aeroponic System.

Nutrient Management Techniques

The major disadvantage of a closed system is the difficulty of nutrient management. Four main techniques are commonly utilized.

Technique 1

Water addition, pH and electrical conductivity (EC) control are all automatic.

The pH is a measure of the acidity of the substrate and controls the availability of mineral nutrients; whereas, the EC gives an estimate of the nutrient content.

The recommended pH for hydroponic culture is between 5.0 and 6.0 because overall availability of nutrients is optimized at a slightly acidic pH, and the EC level should be 1.5 to 3 dS m-1

Technique 2

The water makeup of the holding tank is automatic, usually by float valve, i.e. the tank level is held steady. Here both water and nutrients are being taken, but only water is being replaced. Therefore, the EC will fall until the tank solution is brought up to strength by nutrient addition. The EC is periodically checked and adjusted to the required value by adding nutrient to the tank by hand. The pH is adjusted if necessary by adding acid (dilute sulfuric acid) to lower the pH or an alkali (dilute sodium hydroxide (NaOH) solution) to raise the pH.

Technique 3

The holding tank is partly or completely run down then refilled as a batch by adding water and/or nutrient. The important aspect of this technique is that the effects of the addition are checked.

Technique 4

The holding tank is partly or completely run down then refilled using a standard strength nutrient solution. However, the resultant EC in the system is not checked or adjusted. This technique can lead to disaster.

Nutrient Solutions for Hydroponics

Commercial hydroponic growers need a more accurate control of the components in a nutrient solution to achieve commercial success. Numerous ‘recipes’ for hydroponic solutions are available. Many use different combinations of chemicals to reach similar total final compositions (Table 1).

Table 1. Major element and micronutrient ionic forms and normal concentration range found in most nutrient solutions (Jones, 2005).

Concentration Range

Element Ionic Form mg/L, ppm

Major Elements

Nitrogen (N) NO–3, NH+4 100 to 200

Phosphorus (P) HPO2-4 , H2PO–4 30 to 15

Potassium (K) K+ 100 to 200

Calcium (Ca) Ca2+ 200 to 300

Magnesium (Mg) Mg2+ 30 to 80

Sulfur (S) SO-24 70 to 150

Micronutrients

Boron (B) BO3- 30.03

Chlorine (Cl) Cl– —

Copper (Cu) Cu2+ 0.01 to 0.10

Iron (Fe) Fe2+, Fe3+ 2 to 12

Manganese (Mn) Mn2+ 0.5 to 2.0

Molybdenum (Mo) Mo0–4 0.05

Zinc (Zn) Zn2+ 0.05 to 0.50

Soil versus Hydroponics

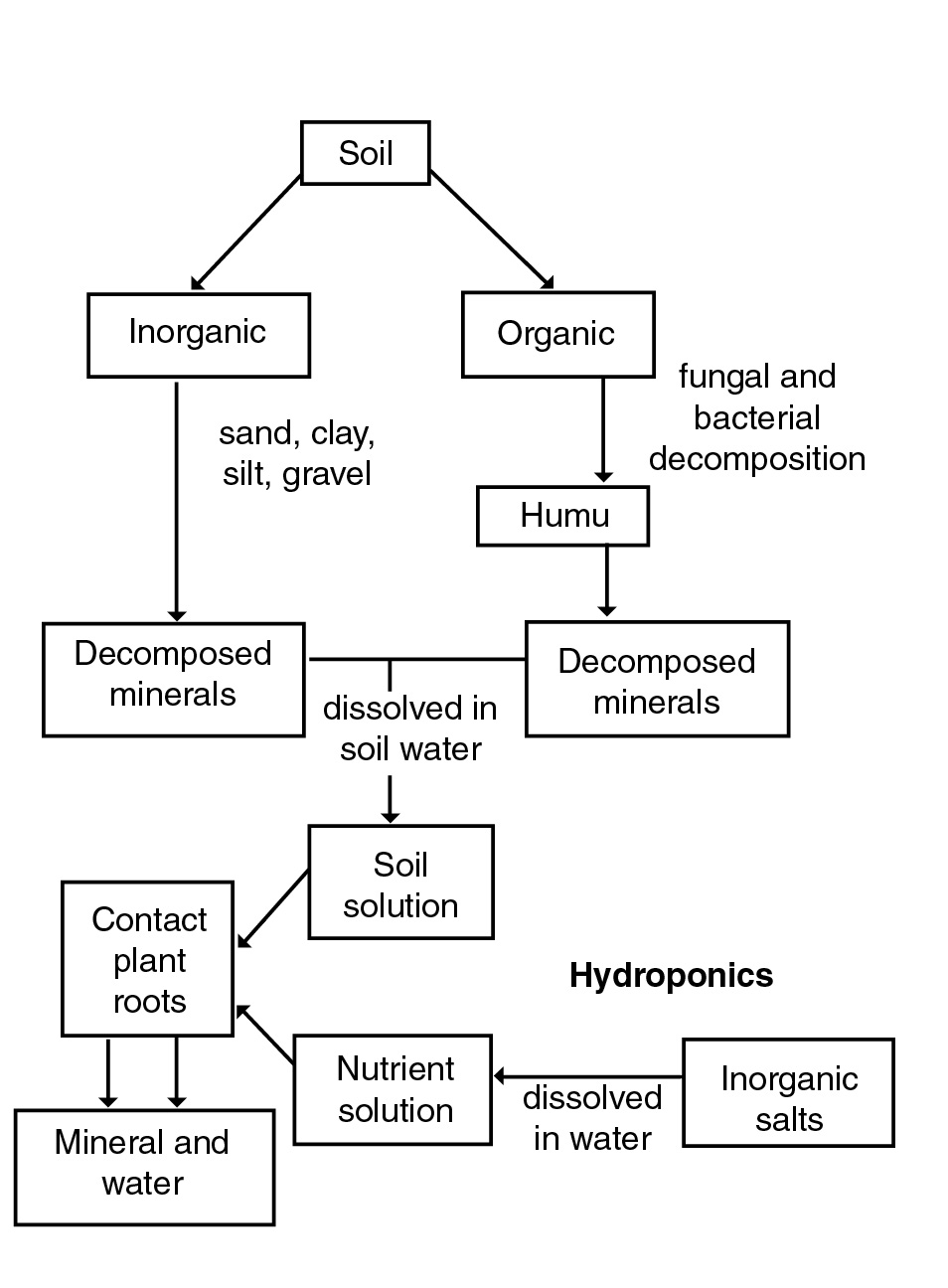

There is no physiological difference between plants grown hydroponically and those grown in soil. In soil, both the organic and inorganic components must be decomposed into inorganic elements before they are available to the plant. These elements adhere to the soil particles and are exchanged into the soil solution where they are absorbed by plants. In hydroponics, the plant roots are moistened with a nutrient solution containing the elements. The subsequent processes of mineral uptake by the plant are the same (Figure 7).

Figure 7. Origin of essential elements in soil and hydroponics.

Nutrition and Hydroponics

There is no conclusive evidence that produce grown hydroponically are more nutritious or healthier than produce grown by any other method, although some small studies indicate that it may be possible. Many countries, such as Holland, do not differentiate whether the produce has been grown by hydroponics or by any other methods; they just concentrate on the quality of the produce. Produce quality is more likely to remain consistent in hydroponic systems, as plants are often less stressed than in other systems.

Hydroponics in the Home Garden

For the hobbyist, hydroponics is a highly technical specialized form of agriculture that has an ever expanding application to everyday use. At the same time, home hydroponic gardens have become so simple that people without a green thumb can be successful in growing flowers and vegetables in their homes. Many of the advantages of commercial hydroponics also apply to the home and hobby gardeners. In many industries, small systems are developed, then expanded for large scale use. Conversely, in hydroponics, large scale commercial production is becoming more common, while it is more of a challenge to make smaller systems economically feasible.

Planning Commercial Hydroponics

Hydroponic systems are only one of the options available when you are considering whether to grow a crop. Planning for a commercial business should, therefore, follow the normal sequence for considering any horticultural enterprise. Don’t overlook soil growing. You need a worthwhile reason to use a hydroponic system instead of soil.

If you do choose to go with hydroponics, you should evaluate the advantages and disadvantages of each type of production system for your crop of interest. For short term crops such as lettuce, the common choice is recirculating NFT or flood and drain gravel channels. For longer term crops or those very vulnerable to root disease, the common choice is nonrecirculating, media-based systems.

During recent years, there have been an increasing number of companies offering a range of turn-key packages. They sell a total package of protected structure, hydroponic and support systems, and often include consulting and marketing agreements.

List of some Hydroponic Suppliers

- American Plant Products and Services

- Horizon Hydroponics

- American Hydroponics

- GreenCoast Hydroponics

- Eco Enterprises

- Better Grow Hydro

Future

Hydroponics may be used in underdeveloped countries for food production in limited space. It is even feasible to grow hydroponically in areas of poor soil conditions such as deserts. The desert sand serves as a good growing medium and seawater can be used to mix nutrient solution once the salts have been removed. The popularity of hydroponics has increased dramatically in a short period of time leading to an increase in experimentation and research in the area of indoor and outdoor hydroponic gardening.

Additional Reading

Jones, J.B. 2005. Hydroponics: a practical guide for the soilless grower. CRC Press. Boca Raton. Fla.

Mason, J. 1990. Commercial hydroponics. Kangaroo Press, Kenthurst, NSW.

Resh, H.M. 2004. Hydroponic food production: A definitive guidebook for the advanced home gardener and the commercial hydroponic grower. Newconcept Press, Inc. New Jersey.

Savvas,D. and H. Passam. 2002. Hydroponic production of vegetables and ornamentals. Embryo Publications. Athens, Greece.

Arjina Shrestha

Graduate Student, Ornamentals

Bruce Dunn

Assistant Professor, Floriculture

General Document Comments 0

0 archived comments